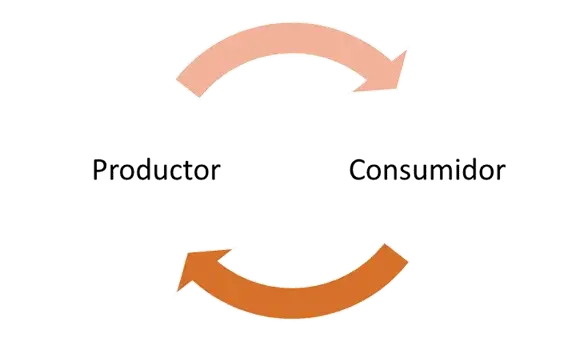

Reverse logistics is an essential component of supply chain management. It encompasses all processes related to the product, such as product return, recycling, reuse and waste disposal. By complementing the standard logistics function of a company, reverse logistics becomes an integral tool to effectively manage the strategic chain between the materials and information offered in this service.

What exactly does reverse logistics involve?

It is a complete process that encompasses the planning, installation and control of the flow of raw materials, process inventory and finished goods from a point of use, processing or distribution to a point of recovery or proper disposal. In essence, reverse logistics is defined as the transportation of goods from one destination to another for the purpose of obtaining value that would otherwise be unavailable.

Within the supply chain

Reverse logistics deals with all activities related to the movement of materials from a point of origin or collection to the consumer. This process involves the treatment of raw materials, finished products, packaging, containers and other types of waste. In this context, materials are reused or disposed of as necessary, thus creating a value- and utility-generating process.

In this sense, reverse logistics deals with the management of product returns and aims to reduce waste to the minimum possible. Optimising reverse logistics return processes helps to reduce the environmental impact and associated costs. Waste management and the management of returned goods are key aspects that are integrated into the reverse logistics strategy.

In addition, the different types of reverse logistics take into account the consumption points and the shelf life of the products. In short, reverse logistics plays a crucial role in supply chain management by ensuring efficient and sustainable management of materials and products throughout their life cycle.

Fundamental objectives of reverse logistics

- Returns: In this section, we discuss a company’s return policy. This is where reverse logistics comes into play, since aspects such as speed and quality of service must be taken into account.

- Care for the environment: The deterioration of the planet is making the population aware of the growing need for the reuse of materials so that the economy becomes more sustainable.

- Economy: Thanks to the reuse of materials, there is a new way of obtaining productivity, since raw materials are recycled and incorporated into new production processes.

- Improved relationship between customers and suppliers

Environment and reverse logistics

Nowadays, society is becoming increasingly aware of the need to care for the environment, so one of the aspects to be taken into account is the recycling and reuse of materials or waste. With this in mind, we can reduce pollution and take care of natural resources by giving the products that are returned another useful life.

Companies often promote environmental care in the following ways:

- Responsible behavior positively influences a company’s protection actions.

- Customers are increasingly demanding environmentally responsible products.

- Public administrations promote respect for the environment by applying preventive measures at local, state and national level.

In addition, reverse logistics plays a crucial role in environmental management by addressing the reduction of environmental impact and the management of returned products. This strategy contributes to minimising environmental care and efficiently managing old products that are returned, thus integrating sustainable practices into the supply chain.

Possible limits to reverse logistics

There are strategic limits that can hinder reverse logistics, such as, for example, product design based on recycling and packaging management.

Design for recycling

The design of the products focuses on profit and environmental care.

Design guidelines:

- Simplify materials: If you reduce the variety of materials, i.e., if you only focus on a few materials, you simplify the recycling process. (For example: plastic, glass…).

- Labeling materials: The raw material of the product must be identified, as this is essential for the correct recycling route. There is established labelling.

- Ease of undoing: By applying this type of development to the product, you provide the company with a breakthrough when it comes to breaking a product, which means savings in costs and management time.

Packaging logistics

The packaging design must also be optimized for reverse logistics.

Characteristics of containers and packaging

- Labeling: It favors the knowledge of the raw material contained in the container.

- Recycled: It must also appear on the label above. It should indicate whether the product is vulnerable to recycling.

- Reuse: There are containers that can be reused, for example, reusable plastic bags versus fabric bags that are not reusable.

- Return: In this case, they are containers that can be returned to the producer, i.e. they are reused without any transformation process. In the past, glass containers were recyclable, but today they are recycled.

The 3Rs: Reuse, recycle and reduce

Any trade is a cause of waste, but due to the consumption boom that was imposed by the market economy, today’s societies generate even more waste than before.

Therefore, the three Rs rule is used, which considers three elements to reduce the impact of waste on the environment.

- Reuse: Consider using items such as containers and packaging more than once to take advantage of their ease of use and life span.

- Recycling: There is a tendency to use products and/or materials that are sensitive to reuse and can be incorporated into future production processes.

- Reduction: Focuses its waste (loss) of materials on those whose recovery and recycling is not possible. Their reduction implies environmental and economic cost reductions.

Why choose reverse logistics?

As we have discussed previously, the rise of reverse logistics has grown due to the importance of environmental concerns. Consumers are increasingly aware of the need for better products and services.

Advantages

- Improve customer happiness

- Reduces environmental impact

- Focused brand image

- Savings in raw material costs

- Customer loyalty

- More competitive customer service

- Cost reduction

- Generates new source of profits

The aim of any logistics strategy is to deliver an optimal level of customer delight and to control end-to-end costs in the delivery chain.

Do you want to know the amount of your shipment in less than a minute?

Request your quote in less than 3 minutes with just one click.